Inadequate ventilation presents many challenges for hog producers, including heightened risks of animal distress, respiratory diseases and reduced productivity. Heat stress is also a significant concern, costing the swine industry approximately $900 million annually1. When pigs experience heat stress, it negatively impacts their health and efficiency. Healthy, non-stressed pigs grow faster, are less prone to illness, and contribute more to the operation's bottom line.

“When pigs are stressed, it can have a variety of negative impacts on their health, behavior and productivity,” said Mark Oberreuter, PE, System Design Engineer and Tech Team Manager at Automated Production (AP). “The pig that is the most comfortable will be the most productive. So anything a producer can do to regulate the barn environment will help improve the pig's health and optimize productivity.”

Understanding the Impact of Inadequate Ventilation

Proper ventilation is more than just airflow. Ensuring your ventilation system functions properly is critical for maintaining a stable barn environment. Adequate ventilation removes excess heat, gases and moisture that accumulates within the barn, promoting the overall health and well-being of the animals and the efficiency of operations.

Inadequate ventilation causes many issues for producers, including:

- Poor air quality

- Heat stress

- Increased respiratory illnesses

- Heightened disease risk

- Animal discomfort and aggression

- Reduced efficiency and growth

- Decreased profitability potential

Commander Series Fans Tackle the Challenges of Hog Barn Ventilation

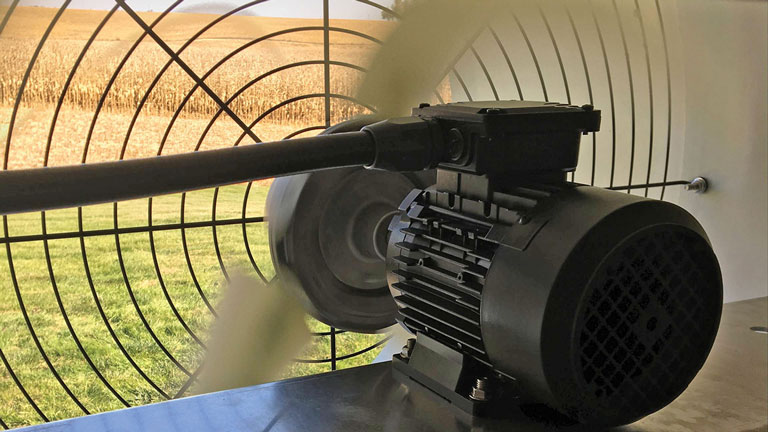

The Commander Series Fan by AP is engineered to tackle the challenges of ventilation in hog barns, providing robust airflow, temperature control and improved efficiency. Its unique design and advanced features make it an essential asset for any hog operation.

Improved airflow and temperature control: The Commander Fan ensures consistent airflow throughout the barn, which is crucial for maintaining a stable and comfortable environment. By effectively reducing heat stress during hot weather and preventing cold drafts during colder months, the Commander Fan helps create an optimal living condition for pigs year-round.

Energy efficiency and cost savings: One of the standout features of the Commander Fan is its energy-efficient design. This fan delivers superior performance and lowers energy consumption, translating into significant cost savings for producers. The fan's efficiency increases as it slows down, optimizing energy use without compromising effectiveness. This is especially beneficial in the transitional spring and fall seasons.

Low maintenance: The Commander Fan is built for durability and ease of use. Without belts, pulleys or grease required, maintenance is minimal. This design ensures that the fan remains operational with less downtime and lower maintenance costs, making it a more efficient and reliable component of ventilation systems.

"Raising pigs efficiently involves optimizing inputs, minimizing costs and maximizing performance while ensuring the pigs grow and thrive," said Oberreuter. “Achieving ideal airflow is crucial for creating the best environment for pigs from a young age. This means maintaining the right temperatures, ensuring adequate oxygen levels and avoiding drafts. Precision in air exchange is essential. As the temperature in the barn changes, it's vital to have equipment like the Commander Fans that can adjust ventilation to meet the pigs' needs."

Optimize Your Barn’s Ventilation System

Does your barn air ventilation system need to be optimized? AP offers comprehensive solutions. Whether you need a new ventilation system designed, an existing one updated or an audit of your current system, AP’s experts can help ensure your barn’s ventilation is in top shape.

For more detailed information on the Commander Fan and how it can benefit your swine production operation or to find a dealer, visit AP's Commander Series Fans.

1 University of Minnesota Extension: https://extension.umn.edu/swine-production-management/heat-stress-swine-affects-production#effects-on-grow-finish-stage-of-production%C2%A0-255312