Hog producers face significant challenges in keeping their livestock well-fed and healthy. Feeding systems often become bottlenecks in production, impacted by frequent clogs, unreliable equipment and increased maintenance costs. Feed blockages are particularly troublesome, leading to costly downtime and unpredictable gaps in feeding schedules, which can affect the overall health and growth of the animals.

An experienced hog producer, Nich Holland underscores the frustration with unreliable feed systems. “The most challenging part is ensuring reliability and longevity. Keeping feed in front of pigs at all times is critical and is what keeps us running.” Yet, without dependable equipment, feeding can become a daily struggle that diverts attention from other tasks.

Reliability, ease of maintenance and consistent feed flow have become essential to sustaining a profitable operation. Inefficient systems compromise feed quality, causing delays and reducing performance. As Holland highlights, inefficient feed systems cost more than just time. “When pigs are out of feed, you don’t get that time or performance back once it’s lost.”

For hog producers, investing in a system that ensures smooth feed flow and minimizes downtime can be game-changing, enabling them to focus more on animal care and less on troubleshooting equipment.

Revolutionizing Feed Flow for Hog Producers

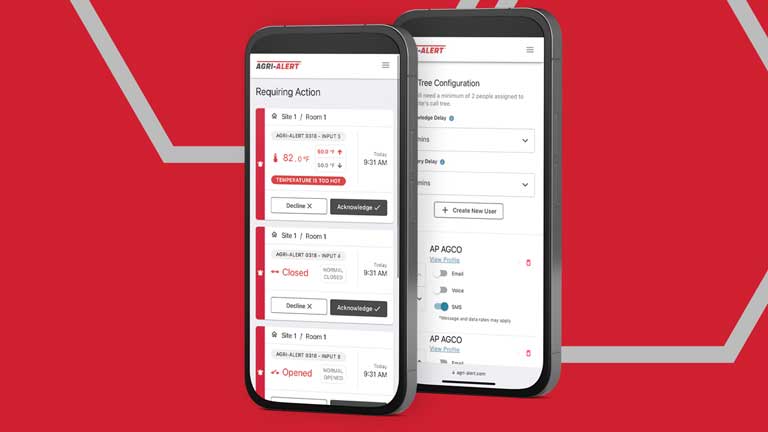

To bridge this gap, Automated Production (AP) introduced the Flex-Flo™ XD Ultra Unloader, a solution designed with hog producers’ pain points in mind. This advanced feed delivery system reduces blockages, increases durability and provides unprecedented ease of maintenance. Holland notes that AP was one of the first companies to address these industry-wide issues with a truly reliable product, which has been well-received by producers needing a long-lasting, effective solution.

Durable, Efficient and Easy to Maintain: Why the Flex-Flo XD Ultra Unloader Stands Out

The unique design of the Flex-Flo XD Ultra Unloader includes a 50% larger boot opening, improving feed flow and drastically reducing clogging risk. Its fiberglass-filled nylon wear plates and modular parts make it more resilient, lasting up to four times longer than traditional materials. The clear access door allows for easy visual inspection without the need to open it, which also minimizes contamination risks.

The Flex-Flo XD Ultra Unloader isn’t just another feed delivery system — it’s a comprehensive upgrade designed to meet the rigorous demands of hog production:

- Enhanced durability: Nylon-infused wear plates reduce damage on augers and significantly increase longevity, eliminating frequent replacements.

- Improved feed flow: The system’s larger boot opening ensures feed flows smoothly, reducing downtime due to clogs and providing a more consistent feed delivery. This prevents “bridging” events that disrupt feeding schedules.

- Easy maintenance: The modular design allows producers to replace individual parts without dismantling the entire system, saving time and labor costs.

- Retrofit compatibility: Flex-Flo XD Ultra Unloader can be seamlessly integrated with existing systems, offering flexibility to producers who may not be ready for a complete overhaul.

Why Hog Producers Should Invest in the Flex-Flo XD Ultra Unloader

Investing in the Flex-Flo XD Ultra Unloader is a smart choice for producers looking to optimize efficiency and reduce costs. By minimizing downtime and reducing maintenance needs, the system boosts productivity and lowers long-term operational expenses. This system also enhances pig welfare, ensuring they always have access to feed, which translates to better growth and productivity.

“Knowing my pigs will be fed without interruption — and that any issues can be quickly resolved — brings invaluable peace of mind,” says Holland. “With this new equipment, I can focus on caring for the pigs, not on whether my feed system will hold up.”

Optimize Your Barn’s Feeding System with the AP Flex-Flo XD Ultra Unloader

Discover how the AP Flex-Flo XD Ultra Unloader can benefit your operation and find a dealer near you.